The Rise of Additive Manufacturing and Its Potential in Production

In recent years, additive manufacturing, commonly known as 3D printing, has gained significant momentum in various industries. This innovative technology has transformed the way products are designed, prototyped, and manufactured. With its ability to create complex shapes and structures that were previously not possible, additive manufacturing is poised to revolutionize production processes across different sectors. In this blog post, we will explore the rise of additive manufacturing and its potential in production.

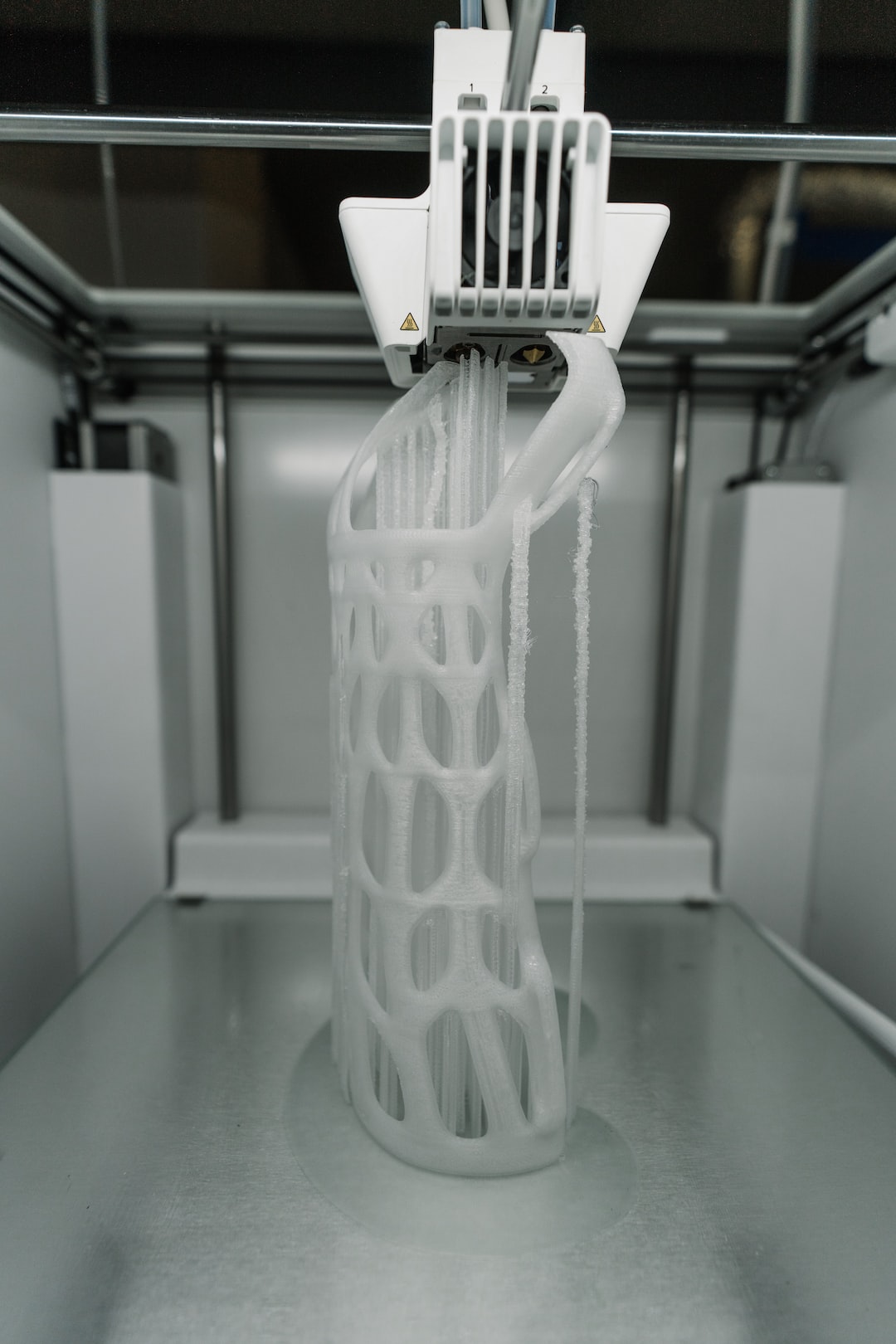

Additive manufacturing, unlike traditional subtractive manufacturing, builds objects layer by layer using digital designs. This process involves the deposition of material, typically in the form of powders, liquids, or filaments, through a computer-controlled nozzle. As each layer is added, the material solidifies, creating a three-dimensional object. The versatility of this technology allows for the creation of intricate geometries that traditional manufacturing methods struggle to achieve. From consumer products to aerospace components, additive manufacturing has demonstrated its potential in various fields.

One of the major advantages of additive manufacturing is its ability to reduce material waste. Traditional manufacturing methods often involve cutting, shaping, or machining a larger piece of material to obtain the desired shape. This results in significant waste material that requires disposal or recycling. On the other hand, additive manufacturing only uses the necessary amount of material required for each specific part, minimizing waste and reducing environmental impact. This not only improves sustainability but also lowers production costs by eliminating the need for excess raw materials.

Another significant benefit of additive manufacturing is its cost-effectiveness for low-volume production. In traditional manufacturing, setting up production lines for small batches can be prohibitively expensive due to the need for tooling and molds. With additive manufacturing, the same cost is incurred regardless of the production volume, making it a more affordable option for small-scale production runs. This has democratized manufacturing, enabling small businesses and startups to compete with larger companies in the market.

Moreover, additive manufacturing allows for rapid prototyping and iterative design processes. Designers and engineers can quickly create multiple iterations of a product, test them, and make improvements based on customer feedback. This iterative design approach ensures that products are optimized for their intended purpose, leading to higher quality and increased customer satisfaction. Speeding up the product development cycle can give businesses a competitive edge in the market, reducing time-to-market and facilitating innovation.

The potential of additive manufacturing goes beyond prototyping and low-volume production. As the technology matures, it is increasingly being used for mass production. Industrial-scale additive manufacturing can significantly streamline production processes, simplify supply chains, and enable on-demand manufacturing. By reducing the need for multiple suppliers and assembly steps, additive manufacturing can lead to shorter lead times and increased flexibility in responding to customer demands. This not only allows for more efficient production but also opens up the possibility of customization and personalization on a mass scale.

Furthermore, additive manufacturing offers unique design possibilities that were previously unattainable. Complex shapes, internal channels, and lattice structures can be easily achieved, enabling the production of lightweight and optimized components. This opens up new opportunities for industries such as aerospace and automotive, where weight reduction is critical for improved fuel efficiency and performance. By leveraging the design freedom of additive manufacturing, engineers can reimagine traditional parts and create more efficient solutions.

As additive manufacturing continues to advance, it is rapidly becoming an essential part of the modern production landscape. Its ability to reduce waste, lower costs, enable rapid prototyping and customization, and unlock new design possibilities has made it an attractive option for industries across the board. While there are still challenges to overcome, such as the limited range of materials and longer production times for large-scale production, the potential of additive manufacturing remains promising. Whether it’s in aerospace, healthcare, consumer goods, or manufacturing, additive manufacturing is undeniably changing the way products are conceived, designed, and produced. The future of production is additive, and we are only just beginning to explore its full potential.